Please ensure that when returning Empty Containers at any TraPac terminal that

all the old placards have been removed. Any Empty coming in with old placards may be

directed out of the terminal to remove.

Thank you for your cooperation

Please ensure that when returning Empty Containers at any TraPac terminal that

all the old placards have been removed. Any Empty coming in with old placards may be

directed out of the terminal to remove.

Thank you for your cooperation

TraPac is pleased to provide a Live Gate Camera view on our website home page for each

TraPac terminal. Under Trucking Companies/Information is a drop down menu to

select the Real time Gate camera. Updated every few minutes to provide the latest view.

https://losangeles.trapac.com/cameras/

https://oakland.trapac.com/cameras/

https://jacksonville.trapac.com/cameras/

TraPac’s terminals are open and operating. Please follow our news section for latest gate updates and changes to gate hours.

Effective 3/16, Los Angeles will begin allocating empty return appointments by Shipping Line. Unused empty appointments will go against the allocation of the shipping line. Please plan accordingly and be sure to cancel unused empty appointments.

Los Angeles, Calif. – March 5, 2020 – TraPac, LLC (TraPac), which operates container terminals in the U.S. ports of Los Angeles, Oakland, and also manages a container terminal in Jacksonville has been awarded Most Improved and Fastest Terminal Awards at DrayTech 2020 presented by Harbor Trucking Association. TraPac ranked first in both the fastest terminal category and most improved category for Los Angeles.

To rate the seven marine terminals in the port of Los Angeles, the Harbor Trucking Association calculated terminal turn-time averages using third-party data provided by GeoStamp. GeoStamp collects data via API web services and a custom GeoStamp mobile application.

“We are very pleased to receive these awards from our partners at the Harbor Trucking Association,” said Stephen Edwards, CEO of TraPac LLC. “Our focus on continuous improvement helps us to meet our mission, which is to provide the fastest, most sustainable and efficient service to our partners. We are extremely proud of our employees for this accomplishment and appreciate their efforts to better serve our customers.”

Weston LaBar, chief executive of the Harbor Trucking Association said, “Our drivers increasingly enjoy doing business at TraPac. They can move their containers faster which allows them to make more money. TraPac is setting a new standard for efficiency and trucker engagement and we really appreciate that.” DrayTech 2020 is presented by Harbor Trucking Association in partnership with JOC.com.

###

About TraPac, LLC

Headquartered in Wilmington, CA., TraPac was established in 1985 to operate a competitive container terminal featuring state-of-the-art technologies and facilities in the Port of Los Angeles. On the U.S. West Coast, TraPac opened the Los Angeles terminal in 1987 and a facility in Oakland in 1990. The Jacksonville terminal was opened in 2009, which is currently owned by TraPac Jacksonville LLC. TraPac manages the Jacksonville terminal on behalf of the owner. TraPac was among the first to make full use of information technology to boost terminal operating efficiency. www.trapac.com

About Harbor Trucking Association

Headquartered in Long Beach, CA., Harbor Trucking Association is a is a coalition of intermodal carriers serving America’s West Coast Ports:

Los Angeles, Long Beach, Oakland, Seattle and Tacoma. The purpose is to advocate, educate and promote strategies with other goods movement stakeholders and policy makers that will sustain emission reductions, provide a dialog for intermodal truck efficiency, and to return cargo and jobs to America’s west coast ports.

Media Contact: Andrea Connolly, 310-513-7481 andrea.connolly@trapac.com

STEAMSHIP LINE INFORMATION

CHASSIS OFFSITE EXAM AND OTHER CONTACT INFORMATION

FIRMS & PORT CODE

Automated Terminals the Fastest Option for Trucking Containers

Source: FreightWaves | July 24, 2019

The ability of marine terminals to move ocean containers quickly is becoming a selling point for shippers frustrated with long delays seen at U.S. ports during the second half of 2018. And one of the fastest terminals on the U.S. West Coast says it is ready for the upcoming peak season.

TraPac’s Los Angeles marine terminal is one year into the first phase of a $510 million upgrade that started in 2013. The project included increasing the terminal’s size by nearly a third to 233 acres, deepening vessel berths to handle post-panamax container ships, upgrading the wharves, and the construction of a new on-dock rail yard.

In its environmental impact report, TraPac said the upgrades were needed to allow the terminal to handle 2.4 million twenty-foot equivalent units (TEU) by 2038, up from 1.7 million TEU in 2015.

Most importantly, the new upgrades allowed TraPac to devote a portion of its terminal for automated container handling for both rail and truck moves. Andrea Connolly, Marketing Manager at TraPac, said automated container handling was a key reason it was able to handle the front-loading of containers into the U.S. last year and why it is seeing some of the lowest turnaround times for drivers at Southern California ports.

“TraPac did see an increase in volumes due to front-loading,” Connolly said. “Our fully automated process enables us to improve safety and avoid unexpected interruptions, such as substantial volume increases that can significantly impact productivity.”

Automation is a fraught topic at the Port of Los Angeles as seen in the recent debate around a project at APM Terminals’ Pier 400 site. Critics of that project point to a McKinsey & Co. survey that found respondents saying that “ports, especially fully automated ones, are generally less productive than their conventional counterparts.”

Connolly declined to address the Pier 400 project. But she said that TraPac has doubled its container capacity thanks to the use of automated cargo handling equipment, such as stacking cranes and straddle carriers.

As for trucking efficiency, Connolly noted that TraPac remains one of the easiest terminals for retrieving containers.

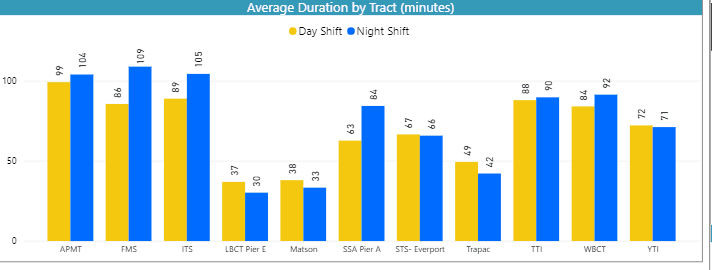

The Harbor Trucking Association’s Truck Mobility Data powered by GeoStamp said TraPac’s average turn times ranged between 66 and 72 minutes during the fourth quarter of 2018, compared to an average of 90 minutes across all Southern California marine terminals.

Source: TMD

TraPac has continued to outpace the rest of the port in terms of truck turns. Since June, it achieved an average 49 minute turn time for the day shift, compared to a 79-minute turn time port-wide. The only other automated marine terminal, Long Beach Container Terminal, likewise sees consistently low turn times.

Those turn times include the non-automated portion of the TraPac site. Boxes moving through the automated portion of TraPac’s yard can retrieve an import container in as little as 15 minutes, Connolly said. She noted that drivers, as well, have an easier time negotiating the terminal as both drop-offs and pick-ups can be done in one location.

“Truckers do not have to travel to more than one location to deliver a container and drop off a container like they would at a conventional terminal,” Connolly said. “This dramatically improves the safety for both drivers and longshore labor and also eliminates harmful emissions from idling trucks.”

Freight companies are paying more attention to turn times to increase driver earnings per day. Uber, Convoy and NEXT Trucking are looking at ways that drivers can find dual-transactions at the port.

“With the automated truck handling system at TraPac, trucks can expect to get in and out of the terminal faster, which means more daily pick-ups and drop-offs,” Connolly said. “Additionally, [beneficial cargo owners] can expect to receive their goods faster than competing terminals.”

Ocean carriers are likewise seeing the advantages of moving goods through TraPac. CMA CGM subsidiary APL changed its Los Angeles terminal call for its premium Asia-to-U.S. West Coast service to TraPac in June.

The Eagle Express Service offers shippers rail transit times between 14 to 17 days from Los Angeles to U.S. Midwest destinations. The service also offers shippers dedicated container yard space, truck lanes and access to container chassis.

Getting APL to switch vessel calls from its Eagle Marine Services terminal to TraPac is a result of the company’s automation investment, “which has allowed us to substantially densify our existing volumes and in turn, free up significant [container] capacity. “

View original article here: https://www.freightwaves.com/news/automated-terminals-the-fastest-option-in-container-trucking

We are pleased to announce that the TraPac website will be accepting AMEX, Diner’s Club, Discover, JCB, Master Card and Visa

for the following transaction types:

Import CET (VACIS)

Import CBP Tailgate

Import Over Dimension Flip Fees

Import Gate Fees for Oakland

Import Sample Fees

eModal will continue accepting all the transactions payments for TraPac,

and Export Gate Fees for Oakland must be claimed thru eModal system.

For Export Over Dimension Flip Fees will be accepted by a company check

Please send the check to the following address:

TraPac, LLC

6500 River Place Blvd.,

Building 2, Suite 250

Austin, TX 78730

We will process with a signed copy of check with an overnight slip

If you have any problem, please contact us at 877-3TraPac.

In order to help accommodate Export Load in appointments we will allow Dual Transactions as follows :

Port Technology, Moving Up and Out

Source: American Journal of Transportation | November 12, 2018

Turn time is the bench mark by which ocean terminals measure efficiency. The longer it takes to move a container on or off the ship or through the facility, the costlier that unit becomes in terms of handling and vessel delay. Container ships aren’t getting smaller; in today’s fast paced world it’s becoming impossible for ports to compete without technology. Automation is not the way of the future; it’s quickly become the norm today.

For years, terminals in Europe and Asia have been vastly superior at container handling. In the States the average ocean terminal performed between 28 and 34 ship to shore lifts per crane per hour. In the yard, conventional rubber tire gantry cranes or yard hustlers move containers into stacks. Both require extensive manpower. In the Netherlands terminal operators were reporting around 41 moves per hour comparatively. As early as 2015 the port of Tenjin Palapas was lifting 81 containers per crane per hour while Shanghai moved 167 containers per lift per hour using tandem hoist cranes under the control of one operator.

Initially the answer could be found in the number of cranes working the ship. Back in 2015 a U.S. terminal would put 3 to 4 cranes against a 12,000 TEU vessel. In Asia where labor was cheaper the port would throw 5 or 6 cranes against the same size ship. As ships got bigger, ports in Europe and Asia realize they had to work smarter moving to dual hoist and quad hoist cranes. In addition, the way containers moved within the terminal had to radically change. America was vastly unprepared for the megaship boom sailing over its horizon.

As mega ships began calling Southern California it became apparent that to effectively move containers, the combination of shore cranes and yard equipment needed to work more efficiently. TraPac Los Angeles was the first container terminal to semi automate their operation. In 2015 TraPac embarked on a project to electrify and automate a portion of its container and rail yards. Utilizing Kalmar technology, a traditional ship to shore crane would drop a single box on the quay to be picked up by automated straddle carriers. Guided by magnets mounted in the tarmac these autostrads moved the boxes to remotely operated stacking cranes or the automated rail positioning crane. Guidance is assisted by advanced laser and GPS technology all controlled from a central operations hub. The days of labor-intensive operations are being replaced by the same workforce handling multiple containers in a shorter period of time. Shift changes are accomplished by one operator standing up and another one sitting down at the same console.

Headquartered in Helsinki, the Kalmar Group offers conventional and automated container handling equipment. Everything from RTG and RMGs (rubber tire or rail mounted gantry cranes) and masted container handlers, what we used to call “high lows” to auto-guided vehicles and automatic stacking cranes. Frank Kho, VP of marketing intelligence, strategy and development at Kalmar noted “In 2020 the container trade will be around one billion TEU. Terminals today are not built to handle this high volume, so they are under increasing pressure to increase productivity.”

Kalmar’s One Terminal concept is the integration of automated yard equipment with NAVIS operating systems. NAVIS, a leader in integrated software, has produced a terminal operating system (TOS) N4 which integrates control of physical handling equipment with container positioning and real time yard activity data. Competitive with TOS providers such as Advantech GMBH Germany and Cirrus Logistics of the U.K., NAVIS headquartered in Oakland has 30 years of experience working with terminal operators to “optimize every facet of facility operations.” TraPac added automation to an existing well-established well-run facility. Across the harbor a massive reconstruction project began in Long Beach.

Around the same time (2008 -2011) as TraPac was renewing its lease and undertaking development plans, the Port of Long Beach was beginning the consolidation of three aging terminals. Piers D, E and F would become the backbone of a new mega facility initially called “Middle Harbor”. The nucleus of this project was OOCL’s Long Beach Container Terminal (LBCT) soon to undergo construction. Phase 1 saw a total renovation of the existing infrastructure, improvements to the width and depth of the quay and a 22-acre landfill at slip 1 to create additional backland. Phase 2 added 40 acres of container yard by connecting the two sections of Pier F and expanding the on-dock rail from 10,000 linear feet to over 74,000 feet. Opening in April of 2016 LBCT was just under 300 acres and fully automated. Speaking about Long Beach Container Terminal its President Anthony Otto commented, “What we wanted it to be was the most technologically advanced most efficient, most cost–effective container terminal in the United States. And I think we have achieved that.”

In order to create perhaps the most sophisticated facility in the United States, LBCT executives traveled around the world to review automation in action. “What we have achieved here is a major paradigm shift in our industry, certainly here in Southern California or for within the United States” Otto said. Driven by technology provided by ABB Ports Zurich, LBCT has fully integrated multi-functional ship to shore cranes with remote controlled yard equipment to create a fully automated container terminal. Combining dual hoist container cranes with remotely driven yard vehicles and stackers the terminal is able to maintain operational consistency across multiple shifts.

Labor has done an outstanding job of adapting workflow within an automated environment. LBCT was committed to providing the training necessary to bring its work force up to the higher skill sets needed to operate an automated facility and according to management they are doing very well.

Scheduled for completion in Q-1-21, Long Beach container terminal will be 311 acres with a throughput capacity of 3.3 million TEU. The 4,200-foot wharf will encompass 3 deep water berths. 14 ultra-modern container cranes equipped with ABB port technology will be able to handle container vessels up to 21,000 TEUs. A remotely operated on dock rail yard will be able to handle 24 trains per week for an annual capacity of 1.1 million TEUs. In a recent interview Otto said, “ABB has been an outstanding partner; they have been involved in every part of this from the rail to the yard to the automated stacking cranes and to the ship to shore cranes. Everything in concert with Navis N4 which is our TOS as well as the TEAMS project for the AGVs.”

Uno Bryfors, senior vice president of ABB Ports noted, “Automation has been maturing and spreading to all sizes and types of terminals. We have delivered automatic stacking crane automation to 27 different terminals around the world each having between 4 and 72 cranes per terminal. In terms of fully automated terminals, Mr. Byfors noted that it will still take some 5 to 10 years before we see these facilities around the world. Remote ship to shore technology has taken hold faster than automated stacking cranes. ABB operates a remote shoreside package in a dozen terminals on five continents. A notable example of full automation at work is APMT’s Maasvlatke II terminal in Rotterdam. Remote operators control all functions from vessel lifts to automated stacking at a central location. Vessel and yard operations run 24 hours a day and as with other ABB facilities shift changes are simply a matter of changing operators. There are no crew change delays. Massvlatke II has a design capacity of 2.7 million TEUs. The terminal operates 10 high speed double trolley ship to shore cranes, 72 auto-guided vehicles and 54 automated RMGs. The eight track on-dock rail terminal connects the Port of Rotterdam with the German border at Zevenaar-Emmerich.

Technology will continue to dominate the construction and redevelopment of ports worldwide. Automated packages as offered by Kalmar and ABB provide “off the shelf” solutions to design and development. The ground has already been broken and it is only a matter of tweaking existing technology. Shoreside labor worldwide has also begun to understand the need for their ports to remain competitive. Concerns for a stable work environment and job security are still important but with mega ships and increased terminal capacity must come that paradigm shift in port productivity. Will labor and management continue to embrace the issue of productivity through automation and allow ocean terminals to move up and out?

View original article here: https://www.ajot.com/premium/ai-port-technology-moving-up-and-out