Automated Terminals the Fastest Option for Trucking Containers

Source: FreightWaves | July 24, 2019

The ability of marine terminals to move ocean containers quickly is becoming a selling point for shippers frustrated with long delays seen at U.S. ports during the second half of 2018. And one of the fastest terminals on the U.S. West Coast says it is ready for the upcoming peak season.

TraPac’s Los Angeles marine terminal is one year into the first phase of a $510 million upgrade that started in 2013. The project included increasing the terminal’s size by nearly a third to 233 acres, deepening vessel berths to handle post-panamax container ships, upgrading the wharves, and the construction of a new on-dock rail yard.

In its environmental impact report, TraPac said the upgrades were needed to allow the terminal to handle 2.4 million twenty-foot equivalent units (TEU) by 2038, up from 1.7 million TEU in 2015.

Most importantly, the new upgrades allowed TraPac to devote a portion of its terminal for automated container handling for both rail and truck moves. Andrea Connolly, Marketing Manager at TraPac, said automated container handling was a key reason it was able to handle the front-loading of containers into the U.S. last year and why it is seeing some of the lowest turnaround times for drivers at Southern California ports.

“TraPac did see an increase in volumes due to front-loading,” Connolly said. “Our fully automated process enables us to improve safety and avoid unexpected interruptions, such as substantial volume increases that can significantly impact productivity.”

Automation is a fraught topic at the Port of Los Angeles as seen in the recent debate around a project at APM Terminals’ Pier 400 site. Critics of that project point to a McKinsey & Co. survey that found respondents saying that “ports, especially fully automated ones, are generally less productive than their conventional counterparts.”

Connolly declined to address the Pier 400 project. But she said that TraPac has doubled its container capacity thanks to the use of automated cargo handling equipment, such as stacking cranes and straddle carriers.

As for trucking efficiency, Connolly noted that TraPac remains one of the easiest terminals for retrieving containers.

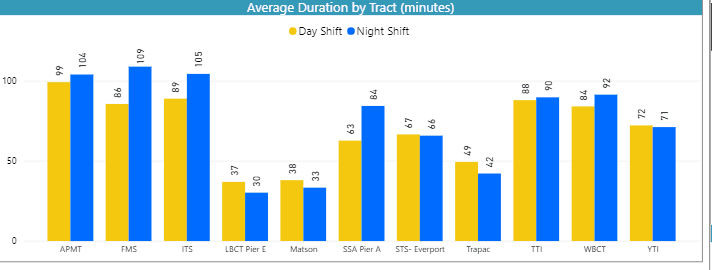

The Harbor Trucking Association’s Truck Mobility Data powered by GeoStamp said TraPac’s average turn times ranged between 66 and 72 minutes during the fourth quarter of 2018, compared to an average of 90 minutes across all Southern California marine terminals.

Source: TMD

TraPac has continued to outpace the rest of the port in terms of truck turns. Since June, it achieved an average 49 minute turn time for the day shift, compared to a 79-minute turn time port-wide. The only other automated marine terminal, Long Beach Container Terminal, likewise sees consistently low turn times.

Those turn times include the non-automated portion of the TraPac site. Boxes moving through the automated portion of TraPac’s yard can retrieve an import container in as little as 15 minutes, Connolly said. She noted that drivers, as well, have an easier time negotiating the terminal as both drop-offs and pick-ups can be done in one location.

“Truckers do not have to travel to more than one location to deliver a container and drop off a container like they would at a conventional terminal,” Connolly said. “This dramatically improves the safety for both drivers and longshore labor and also eliminates harmful emissions from idling trucks.”

Freight companies are paying more attention to turn times to increase driver earnings per day. Uber, Convoy and NEXT Trucking are looking at ways that drivers can find dual-transactions at the port.

“With the automated truck handling system at TraPac, trucks can expect to get in and out of the terminal faster, which means more daily pick-ups and drop-offs,” Connolly said. “Additionally, [beneficial cargo owners] can expect to receive their goods faster than competing terminals.”

Ocean carriers are likewise seeing the advantages of moving goods through TraPac. CMA CGM subsidiary APL changed its Los Angeles terminal call for its premium Asia-to-U.S. West Coast service to TraPac in June.

The Eagle Express Service offers shippers rail transit times between 14 to 17 days from Los Angeles to U.S. Midwest destinations. The service also offers shippers dedicated container yard space, truck lanes and access to container chassis.

Getting APL to switch vessel calls from its Eagle Marine Services terminal to TraPac is a result of the company’s automation investment, “which has allowed us to substantially densify our existing volumes and in turn, free up significant [container] capacity. “

View original article here: https://www.freightwaves.com/news/automated-terminals-the-fastest-option-in-container-trucking